Master Thesis

Master ThesisAbstract

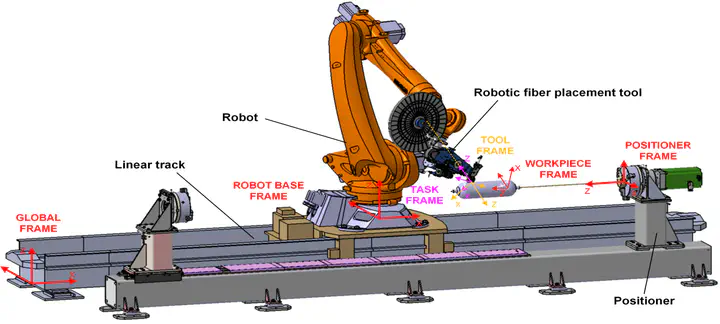

Composite materials offer attractive properties compared to the traditional structural materials, such as high strength-to-weight ratio, exibility in shaping and corrosion resistance. They are therefore being extensively used in various industrial sectors, especially aerospace and automotive industries. The traditional methods of fabrication by manual tape laying are labour intensive, time consuming and less efficient. To overcome these drawbacks and to keep up with the growing competitiveness, the enterprises look towards Automated Tape Winding for manufacturing composite components. Automated Tape Winding is a fabrication process in which the workpiece liner is mounted on a rotating mandrel and heated fibre tows are consolidated over it with a compaction roller mounted, on an industrial manipulator. The robotic cell, comprising of a 6-axis robot and an actuated positioner, is kinematically redundant with respect to the considered task of tape winding. To exploit this redundancy to its full potential and to compensate for high raw material costs of composites, it is essential to optimize the tape winding process. This master thesis work, completed within the framework of EMARO+, proposes a comprehensive methodology for optimizing the robot and the positioner trajectories with improved kinematic redundancy management. This work was realized in collaboration with the industrial partner CETIM’s technological platform named, SPIDE-TP Platform, with the ultimate aim of the increasing the overall productivity of an Automated Tape Winding process. In this work, the industrial platform was modelled in a CAD environment. The robot and positioner motions were optimized by following a graph-based search using dynamic programming and complemented with intensive collision detection on the CAD model. The simulation results promise to reduce the processing time by one-third.